BODOR - A Series, E Series, F Series and G Series

If an enclosed laser system doesn’t suit your application, process or allow for your material loading, Bodor's range of open laser cutting machines may be the answer.

You may already have an enclosed space available, if so, please remember that the area must comply to all the necessary standards for laser safety and anyone working or running the tool must wear the appropriate PPE (EN207 eyewear, etc). But if these criteria are met an Open System provides a much higher degree of flexibility that an enclosed laser cutting system cannot offer.

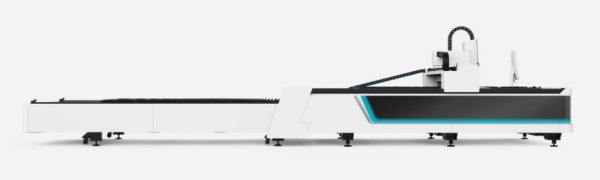

A Series - cost-effective, economical plate fiber laser cutting

Choice of 1000w/1500w/2000w laser source, single-platform design is both practical and economical.

Features

Automatic focusing function of laser head

By setting perforation focal length and cutting focal length respectively, the cutting is more accurate.

Suitable for multiple focal lengths, and focal position will be automatically adjusted based on thickness of different sheets.

Tenon-and-mortise type plate welding structure bed

Use Chinese traditional tenon-and-mortise structure to provide stronger bearing capacity.

Solder joint fixing and structural bearing ensure long-standing operation stability.

Brand New Modular Platform

The modular platform framework prevents deformation caused by heat and facilitates parts replacement.

Bodor Pro Operating System

- Intelligent Layout of Graphics

- Desirable Software Interactions

- Optimal Logic Programming

- Stunning Operating Experience

Intelligent Alarm Function

Finding equipment abnormal in advance and reducing hidden dangers can multiply improve the equipment troubleshooting efficiency.

E Series - exchange platform laser cutting machine

Features

Dual-platform Automatic Exchange System

Rapid exchange between two platforms greatly improves work efficiency. Chain drive reduces loading time, exchange in 30 seconds.

Automatic Nozzle Changer

Adopting accurate control system to automatically replace the nozzles by different material and thickness.High-precision drive system provides a reliable replacement precision and stability.Newest automatic calibration and cleaning functions achieve fully automatic laser head calibration and nozzle cleaning reduce repetitive manual labour.Fully enclosed protection of the whole equipment improves the safety performance of parts and human safety.

Cast Iron Bed

- The usage of flake graphite with a minimum tensile strength of 200MPa enables strong shock absorption and wear resistance.

- High carbon content, high compressive strength and high hardness.

- Low thermal sensitivity and bed gap sensitivity reduces the loss of equipment in using, maintains stable and long-term precision without deformation in a life cycle.

Auto Focus Laser Head

Applicable to multiple focal lengths, automatically adjusts focal position in cutting process by different sheet thickness.

- Focal length is controlled by operating system, which has no more manual regulation, less errors or faults.

- Adopting Bodor lightning perforation technology, with 90% work time reduced. Auto focus laser head can automatically read system storage parameters when changing different metal sheet, which realizes cutting perfectly with less gas, electricity, lower cost, high efficiency.

- Setting perforation focal length and cutting focal length respectively to enhance the accuracy.

- Built-in double water-cooling structure ensures constant temperature of collimating and focusing components, prevents lenses from overheating and prolongs service life of lenses.

Touch Control

The new 21.5 inch touch display with larger area and more convenient operation. 10 touch points ensures more operation accuracy.

Intelligent WIFI Remote Assistance

Global real-time feedback provides fault analysis and troubleshooting in time.

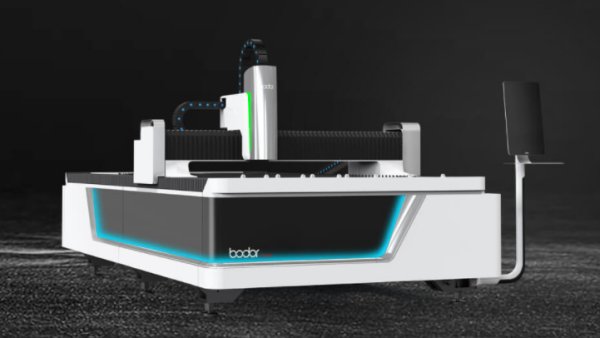

F Series - metal sheet laser cutting

Features

The heavy bed makes the equipment more stable in working, the light crossbeam makes it work faster; perfect industrial design is more in line with man-machine engineering; high quality electrical software control system gives equipment higher cutting precision. The machine owns more comfortable operation, more stable performance, more durable quality, higher cutting efficiency and wider application scope.

Intelligent travel protection

Automatically monitor operation range of crossbeam and cutting parts, keeping operation within machining range. Double guarantees of fixed limitation greatly improve equipment and personal safety, minimizing the using risks.

Auxiliary gas low pressure alarm function

Providing real-time pressure detection, pushing abnormal information when pressure value is lower than optimal cutting effect and precision. Ensure the cutting performance, accuracy and timeliness of gas replacement.

WIFI remote intelligent assistance

Global real-time feedback ; Providing real-time fault analysis and troubleshooting.

Intelligent alarm system

The system will start full abnormal alarm and push it to the interface through control center when equipment is abnormal. Finding equipment abnormal in advance and reducing hidden dangers can multiply equipment’s troubleshooting efficiency.

Durable Cast Iron Bed

Using flake graphite cast iron, the lowest tensile strength of which is 200MPa. High carbon content, high compressive strength and high hardness. Strong shock absorption and wear resistance. Low thermal sensitivity and bed gap sensitivity reduce the loss of equipment in using, so the machine accuracy could maintain for a long time, and no deformation in a life cycle

Auto Focus Laser Head

Applicable to various focal lengths, which are controlled by machine tool control system. Focal point will be automatically adjusted in cutting process to achieve the best cutting effect of different thicknesses sheets metal.

Intelligent Anti-collision

360°radar system can detect any obstacles in advance and Z axis high-speed motion will be activated to imme diately avoid obstacles, avoiding collisions.

Higher Efficiency, Lower Cost

This function Lowers the damage rate of laser head, and accordingly reduces maintenance cost, prolonging service life of the machine. Avoid production halt caused by collisions, ensuring continuous production.

G Series

A high-end, smart, ultra large format laser cutting machine.

Features

The G Series will cut a wide range of metal plates of different areas. These are high security and performance cutting machines come along with intelligence.

- Ultra Large Cutting Area - up to 24,500mm 3,200mm

- Active Anti-collision Function - reduces the damage rate of laser heads and save maintenance costs

Active Anti-collision Function

Effectively reduce the damage rate of laser heads, help you save maintenance cost.

Gas-saving Nozzle with Steady Flow

Cutting performance and efficiency are improved by maintaining a steady gas flow with less turbulence.

Expert High Speed Cutting Database

- Carbon Steel Oxygen Fast Cutting (COF) - thick plate cutting realizes to doubles the speed while ensuring the cutting quality.

- Carbon Steel Economic Fast Cutting (CEF) - at a specific power, cutting cost is only 10% of nitrogen cutting and creates more economic value for clients.

- Low Nitrogen Pressure Fast Cutting (LNF) - the nitrogen pressure reduces to 4Bar during cutting the 10mm stainless steel, its speed improves at least 10% than common cutting.

- Gas-saving Nozzle with Steady Flow - cutting performance and efficiency are improved by maintaining gas flow steady with least turbulence.

Pyramid Structure Crossbeam

Using the optimal design of honeycomb cavity combined with pyramid external structure, the dynamic responding speed of the crossbeam increases.

For more information on any of these systems please contact TLM Laser or return to the metal cutting laser machines page.