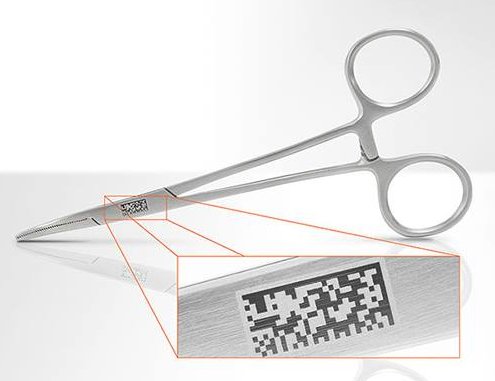

Re-Marking Surgical Equipment.

To be effective, an autoclave must reach and maintain a temperature of at least 121ºC for at least 30 minutes by using saturated steam under at least 15psi of pressure.

Subject to 100s of such treatments, even the most indelible of laser marks is likely to fade. Should it be the UDI mark that is fading or becoming illegible then essential traceability and/or safety information is vanishing with it, making the equipment unusable.

Many reusable items of surgical equipment such as scalpels and forceps are not necessarily high value. But when these items along with other such equipment such as saws, retractors, reamers, etc. need replacing in their 1000s, the cost becomes considerable. Especially if reusable specialist surgical equipment needs replacing when just one individual piece can have a value of several thousand pounds.

That’s why many hospitals and Trusts are prolonging the lives of their reusable surgical equipment by re-marking them. Some have set up their own laser marking facility, others are contracting such work to an outside job shop.

No tooling, more speed

A large hospital that sets up its own laser marking facility will be re-marking 1000s of items of equipment.

With so many items to mark, using fixtures to set the position of the pieces prior to marking is both costly and time consuming.

Our product partner, FOBA, has address this issue of accurately aligning the mark through their MOSAIC vision system. Using the internal camera of the laser to create an image of the marking field, MOSAIC simulates a straight down camera view. This eliminates the side view distortion of an external camera and enables the system to accurately mark parts, regardless of their placement in the marking field.

The big picture

MOSAIC uses lots of small pictures to create one big picture – just like a mosaic! This big picture can be used for training, job set-up, part validation, pre-mark verification as well as mark alignment.

Parts and instruments can be placed loosely in the marking field with absolutely no need for any fixture. Marking will always be aligned and marked perfectly.

In addition, because the operation is fixtureless, significant cost savings can be made, along with the cost of the equipment itself. The marking process is faster and easier, saving both time and the need for intensive operator training.

For further information and details of the benefits of FOBA MOSAIC in a hospital environment, please contact sales@tlm-laser.com

Smaller hospitals or those with fewer items to mark who don’t need an internal laser marking facility, may want to take advantage of our own medical equipment specialist marking service. Again, for more details please contact sales@tlm-laser.com

More information on Laser Medical Marking