Plastic Fantastic! Laser Plastic Welding

Why laser plastic welding is the joining technology of now.

Fast, reliable and inexpensive, providing simple product solutions as well as opening up new applications and markets – it’s no wonder that laser plastic welding is growing so fast. The technology has made notable inroads into the automotive and medical sectors and is moving into a whole range of different industries – wherever plastic is used.

Sensor-Electronic Assemblies

Sensor-Electronic Assemblies

In the automotive industry, laser plastic welding is attractive not simply through its economic advantages but in the quality and smoothness that the technology generates, especially in sensor-electronic assemblies. An example of a more unusual use for laser plastic welding by a car manufacturer is in rear view cameras.

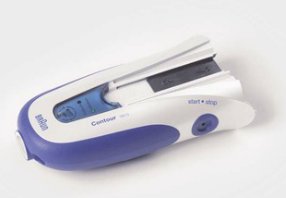

For the medical sector, laser plastic welding is the ideal solution in welding seams in the micrometer range. In microfluidics, precision is combined with particle-free processing, avoiding contamination. Other areas of application include consumables and inexpensive consumer goods.

Transmission Welding

The transmission welding technique is at the heart of laser plastic welding. A plastic material that is transparent to the laser wavelength lies on top of one that is absorbent. The laser beam penetrates through the transparent component and melts the surface of the absorbent material. Through conduction, the heat transfers to plasticise the adjacent surface of the plastic material. A repeatable quality weld is thus created with the two parts of the joint cohesively bonded.

The Secret of Success

The secret of the success of this technique is not the laser but the pressure on the weld created by the lamping process. The clamping tool must press the parts together with a defined pressure that is absolutely uniform across the joint.

Different methods of transmission welding include:

- Contact Welding - where the laser moves relative to the component, particularly useful with large components.

- Simultaneous Welding – where the entire welding seam is heated at the same time, recommended for extremely high production runs.

- Quasi-Simultaneous Welding – a combination of contact and simultaneous welding. A mirror guides the beam along the welding contours at high speed so the entire joint is heated and melted simultaneously.

Leading the Way

The undisputed leader in plastic welding systems is the German company EVOSYS. Much of the company’s success is due to its innovations in quasi-simultaneous welding. The EVO 3800 is a completely integrated, secure, class 1 laser welding process often used in welded assemblies and parts in vehicles such as:

- Rear view cameras

- Tire pressure sensors

- Coupling sensors

- Crash sensors

- ABS and ESP control units

- Head-Up display modules

As EVOSYS product partners in the UK, TLM Laser works closely with its customers in selecting the right laser plastic welding system to meet their needs. Using EVOSYS resources and their own extensive practical experience, TLM can provide advice on materials and help create the optimum clamping tools.

For details and data sheets of the EVOSYS range see; plastic welding solutions or visit sales@TLM-laser.com