Marking Time: from 18 to 3 Hours

One of the top tier suppliers to some of the largest OEMs in the medical industry had a marking and productivity challenge.

With ISO 9001 and 13485 certifications, the company has a reputation for superior quality, cost-effective products manufactured to tight time-lines.

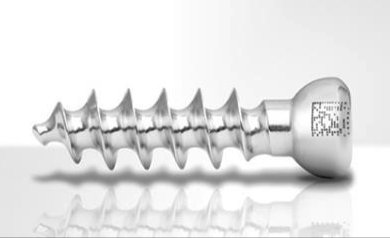

As a medical product supplier, marking is an essential part of the overall manufacturing process. UDI codes must be reliably machine-readable to guarantee full traceability throughout the entire product lifecycle. Brand logos, trademarks and quality signs are required to provide protection against counterfeiting. Cylindrical devices require depth gauges to ensure treatment safety.

Cylindrical challenge

It is with cylindrical devices such as bone twist drills that the company faced its most complex marking task. The problem was in marking these parts with wraparound text.

To achieve the necessary accuracy, numerous different manufacturing steps were required. As a result, set up was taking 6 hours. Another 12 hours were required to then shoot 20 pieces in 12 operations – 18 hours in total.

83% time saving

With its large marking field size of 970x490x450mm (38.19x19.29x17.71in), optical mark alignment and high performance and easy to use software, the company decided that the largest of FOBA’s M series laser marking workplaces, the M3000-P, was the solution.

Like all the laser systems in the M-series, the system can be supplied with customer-specific optional features.

To help turn an 18 hour process into a 3 hour one, the company made full use of the large marking field combined with its three programmable marking axes (X, Y, Z). It also added a rotary to turn cylinder parts in the machine in order to answer particular marking challenges.

Integrated vision

FOBA’s vision systems are integrated into the scan head of the marking laser to facilitate the alignment of the laser mark.

Validation and verification steps are undertaken before and immediately after marking to prevent errors and ensure repeatable results.

With the FOBA MarkUS software package, the company benefits from a convenient laser interface. The integrated vision system and Advanced Operator Plugin delivers a fully visualised marking process.

For full details of how the FOBA M3000-P could be the solution to your productivity problems, please contact sales@tlm-laser.com