Lasers Fumes and Health

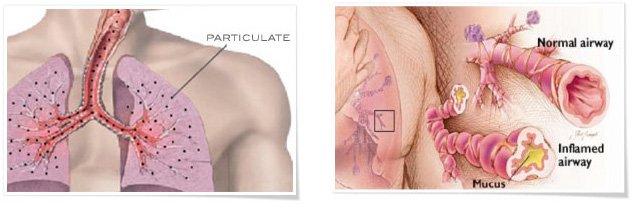

In virtually every laser application, some kind of fume is given off. These fumes are a mix of particulate and gaseous matter also known as Laser Generated Airborne Contaminants (LGAC).

With materials such as metals and glass, the fumes consist mainly of particulates, most of which are less than 1 micron in diameter. Organic materials produce much more complex fumes which are a mix of particulates and gaseous compounds known as Volatile Organic Compounds (VOCs).

Dust particulates of any kind are classified as a substance hazardous to health under COSHH when it is present at concentrations in the air equal to or greater than 10/m3. This figure is for inhalable dust as a time-weighted average over an 8-hour period. For respirable dust, the figure for the same period is much lower – 4mg/m3. Almost all particulates generated in most laser applications are sub-micron sized and therefore respirable.

Marking applications generate typically generate up to 1mg/s of fume and cutting applications in excess of 10mg/s.

Occupational Exposure Limits

A considerable number of the Volatile Organic Compounds produced by lasers have occupation exposure limits set for them. No surprise when some of the gases released include formaldehyde, hydrogen chloride and phosgene, all of which are extremely toxic.

Problems Caused by LGAC's (Laser Generated Airborne Contaminants):

Without filtration, laser fumes don’t only affect operator health.

Laser optical systems are susceptible to damage from particulates getting burnt into the lens. Marking applications on open containers can result in particulates settling inside the containers, contaminating the product being filled.

Filtering out the Harm

Our product partners, BOFA, have unrivalled expertise in fume extraction and filtration. The company’s range of Advantage systems are designed specifically to extract the particulates and gaseous volatile organic compounds generated by laser applications.

Effective particulate and fume removal hinges on the performance of the filtration system. In BOFA’s Advantage range, there are three stages of filtration. A pre-filter is used to protect the stage 2 higher cost HEPA (High Efficiency Particulate Air) filter. BOFA’s Advantage pre-filters have a high degree of particulate separation. With an efficiency grading of F8, they filter 95% of particulates at 1 micron and 80% at 0.2 microns.

Micro Filtration

BOFA Advantage micro-filters are positioned within the extraction system in such a way that all the remaining particulates are captured and held within the media. This is not the case with conventional reverse airflow systems where particulates can fall away and land on the outside of the filter creating a health risk.

The last stage is gas/chemical filtration which is carried out by filters made up of a 50/50 mix of Activated Aluminium Potassium Permanganate and Active carbon. Where PVC is lasered, an additional gas media should be introduced to neutralise harmful and extremely corrosive Hydrogen Chloride gas.

With any extraction and filtration system, it is important that it is an accurate match for the specifications of your laser.

To find out which BOFA Advantage fume extraction system will meet your legal obligations and protect the people you employ and work with, please contact us at sales@tlm-laser.com