Laser Deposit Welding with Powder

You can now weld powder with the Alpha Laser ALFlak 900F and AL-TW 900F fiber laser systems.

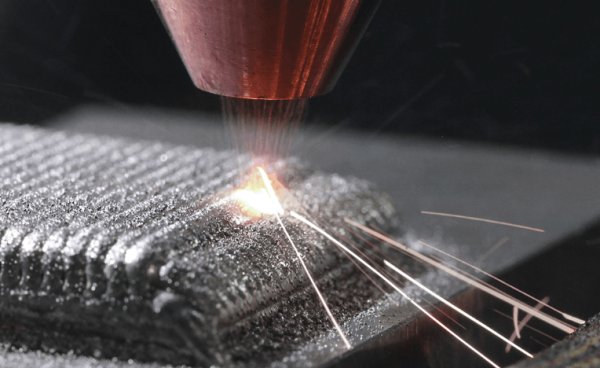

To achieve this Alpha Laser have developed the AL-FLOW Powder Nozzle. This allows metal powder to be transported into the laser focus and welded onto the component by the laser's energy. The option is completed by a powder conveyor that can be supplied with or without mass flow controller.

Laser Powder Nozzle

With the AL powder nozzle material can be deposited to surfaces, lines or arbitrary geometries. Through this, multilayer coating of materials of almost any thicknesses can be achieved and 3D volume can be generated.

Deposit Welding Uses

Laser metal deposition with powder has a range of uses and the process is ideal for plating as protection against wear. Coating with abrasive-resistant materials will significantly increase the service life of components - even under the most adverse conditions. Because laser cladding allows the joining of different materials it can provide a combination of the best material properties. It can also be used for gap bridging during joining.

Laser deposit welding is also suitable for repairs in which pre-programmed geometries are filled in or built up. This means that large-scale material application can be carried out quickly and efficiently.

Contact sales@tlm-laser.com for more information about Alpha Laser's Powder deposit welding option.