Engraving Benefits of RF Excited Lasers

When buying a CO2 laser for cutting and/or engraving, you have a choice between a Direct Current (DC) or Radio Frequency (RF) excited laser tube. DC excited laser tubes are usually made of glass containing a mixture of gases. Electricity excites this mixture which results in an electrical discharge which goes on to create a photonic laser beam.

As an alternative to using electrical energy to excite the gases, RF excited tubes use radio frequency. This produces a pulsed laser with extremely fast repeatability.

Consumable Costs

DC excited lasers are cheaper if the capital cost price is your only criterion. However, that is ignoring the cost of consumables. A DC tube needs replacing once a year or more. In some cases, tubes “go” in just hours. In fact, it could be minutes! DC tubes are delicate devices and can be damaged by routine handling or thermal shock from an interruption in the water cooling supply.

Once a tube goes, you’ve got the problem of disposal. DC tubes are not hazardous, but it’s still an unwanted hassle.

RF tubes will last 50,000 hours+. They are more expensive but in terms of long term ROI, they will end up saving you money.

High Performance

If your laser is to be used purely for cutting then, in speed and quality terms, there’s little to choose between DC and RF.

However, if you need your laser for engraving, RF lasers have a considerable edge. In pulsing terms, DC lasers have only 25% of the speed of an RF excited laser.

RF lasers also generate a smaller spot size and the smaller the spot size, the finer the engraving detail. For high precision engraving, RF excited lasers make a noticeable difference over their DC counterparts.

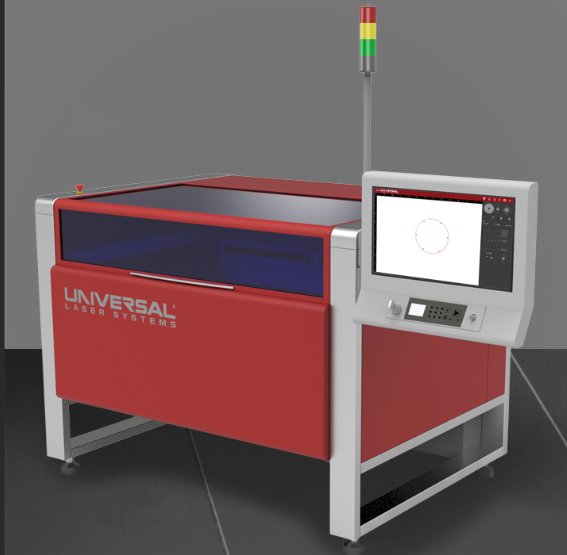

RF Innovators

TLM’s product partners, Universal Laser Systems (ULS) are innovators in RF excited laser systems. RF (or metal laser) technology has its roots in military developments undertaken in US Department of Defence contacts back in the late 1980s.

ULS have taken these developments forward through highly optimised RF excited solutions with an integrated air-cooled metal core CO2 laser source. Using a combination of technologies, these solutions are compact and allow both pulsed and continuous wave (CW) operations that are indefinitely maintainable.

ULS lasers range from 10 watts to 500 watts output power at both 10.6 µm and 9.3 µm wavelengths.

For full details of the Universal Laser System range and how you can improve your laser engraving productivity and profitability, please contact sales@tlm-laser.com