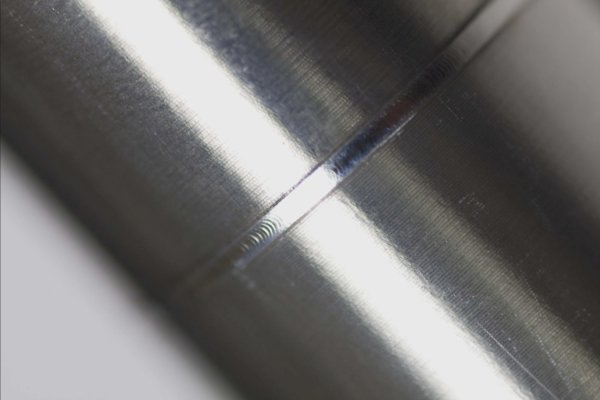

Butt Welding with a Laser

A butt weld, sometimes called a seam weld, is a clean joint between two pieces of metal, wood, or thermoplastic which are aligned in the same plane and where the pieces do not overlap.

This is the most common type of weld and is used to fit together pieces of sheet metal and pipe work and even the rims of bicycle frames.

A Simple Joint

The advantage of this type of weld is that it is a simple joint and, when performed correctly, is a relatively stress-free connection. Some disadvantages of the butt weld are that much care is needed to prepare the two edges to be joined together and they usually have to be bevelled. Also, the heating process to create the weld may not transfer correctly between the top and bottom of the pieces to be joined. Sometimes the result is that the weld may distort.

Arc Welding

Butt welding is commonly performed using metal arc welding or metal inert gas (MIG) welding. This requires the creation of an electric circuit between the material to be welded and the heat source. It also requires the welder to wear protective clothing. The weld itself needs to be flattened with a hammer and any slag and distortions need to be removed.

Laser Welding

When a laser is used as the welding heat source, there is no need for an electric circuit. The laser has a greater accuracy when targeting the surfaces to be joined together. The process may be designed so that the laser penetrates the top of the material to be welded and through to the bottom where it melts the material. The resultant heat then transfers back to the top of the sheet to create an efficient weld.

The laser welding process is also faster, cleaner and cheaper.

Also see Laser Welding Systems