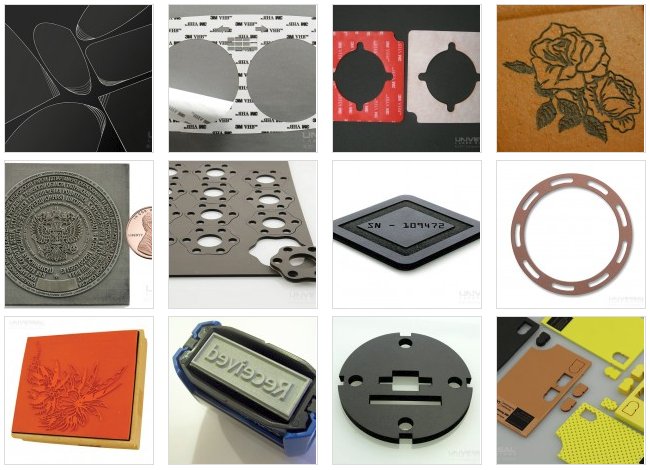

Advanced Materials Processing

Our product partner, Universal Laser Systems (ULS) offers a key support resource to its laser system customers. The company’s Advanced Materials Processing Centre gives customers access to advanced laser processing information and technology to assist and support their production process decision making from configuration to deployment and beyond.

Decades of Research

At the Centre’s core lies the Intelligent Materials Database. This is integrated into the laser system control software available on all ULS systems.

Built on several decades of research, the Database is the most extensive repository of laser materials processing parameters for laser systems ranging from 10 to 500W. The Database calculates optimised laser material processing settings for hundreds of materials.

Settings no longer have to be developed by trial and error. The system takes into account the material and thickness, the process (cutting, engraving, marking or a combination of these) and the laser system’s specifications. It then provides settings that deliver the optimum quality results through the simplest possible process.

3-step Process

The Intelligent Materials Database reduces the sheer complexity of the laser processing of materials to a three stage process – selecting the material, entering the material’s thickness, choosing the process.

To provide the user with these simple three stages, the Database takes into account a wide range of considerations.

For material considerations, the Database accesses ULS’s Materials Library – the world’s premier source for information on laser material processing and the type of material that can be laser processed. The depth of the material is also considered in cutting and engraving applications to achieve the highest possible throughput.

Materials respond differently to laser sources of different power levels. The Database automatically adjusts the processing parameters to account for any laser configuration. For example, it can provide solutions from using a single 25W laser to cut ¼"ABS to using dual lasers with 40 and 50W to mark granite.

All-round Benefits

Improved productivity is an immediate benefit of the Intelligent Materials Database. The need for “trial and error” with regard to establishing processing parameters is eliminated. Time is saved and so is the scrap generated.

Safety is also increased. Working with the wrong parameters, the laser could ignite the material. This could damage the laser itself and the production facility and endanger the lives and heath of nearby personnel.

The Intelligent Materials Database mitigates these safety issues by selecting parameters that have been rigorously tested in actual laser systems by laser processing experts.

For further information on ULS laser systems and the company’s unique Advanced Materials Processing Centre and associated Intelligent Materials Database, please contact us at sales@tlm-laser.com