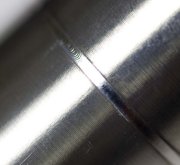

Laser welding has become a part of many manufacturing processes over the past 20 years in industries as diverse as jewelry making and ship building.

One of the main advantages of laser welding metal is that lasers require less heat input compared with other welding processes. Lasers also produce only a small heat affected zone (HAZ) on the welded material and the distortion produced by the welding is low. These attributes, combined with very high speeds, make laser welding an obvious choice for many manufacturing businesses.

Laser welding has become an integral part of medical and manufacturing processes over the past two decades, from hair and vein removal, jewellery repair and microelectronics, to ship building and automotive assembly.

The main advantages are that lasers require a low heat input compared with other welding processes. In addition, they produce only a small heat affected zone (HAZ) on the welded materials, the distortion produced by the welding is low and can be completed at very high speeds.

- See more at: http://tlm-staging.waterbrand.com/info-centre/news-and-events/laser-welding#sthash.EsO3TX9f.dpuf

Laser welding has become an integral part of medical and manufacturing processes over the past two decades, from hair and vein removal, jewellery repair and microelectronics, to ship building and automotive assembly.

The main advantages are that lasers require a low heat input compared with other welding processes. In addition, they produce only a small heat affected zone (HAZ) on the welded materials, the distortion produced by the welding is low and can be completed at very high speeds.

- See more at: http://tlm-staging.waterbrand.com/info-centre/news-and-events/laser-welding#sthash.EsO3TX9f.dpuf

There are four main weld configurations.

- Butt Welding: when the parts to be assembled all lie on the same plane.

- Fillet Lap Welding: where the edge of one material is melted to join the surface of another material.

- Overlap Welding: where the materials lie on top of one other.

- Flange Welding: where two pieces of material are bent and their edges fused together.

Two common types of laser welding technologies are Nd:YAG and CO2. Both lasers operate in the infra-red part of the electromagnetic spectrum. The Nd: YAG is a low power laser that can be highly focused while CO2 lasers are generally more powerful.

Typical fields of application for laser welding are:

- Mould and tool construction or repair

- Thin sheet and precious steel production

- Repair of turbine blades, machine components, housings, etc, in machine construction.

- Medical part production

- Sensor production (micro-welding, tube cutting, scribing, etc.)

- Precision Engineering

- Dental Technologies

- Jewellery Production and Repair

For more information see:

Or contact us for more information.