The Optimum Choice for 3D Printed Parts Repair

Tools, moulds and dies – laser welding is acknowledged as a superior technology in repairing defects in any type of tooling. What’s more, these repairs can be carried out in a wide range of materials including stainless steel, aluminium, copper alloy, cast iron and many plastics. Now this same technology adds a new string to its bow – 3D printed parts repairs.

Meeting the challenge

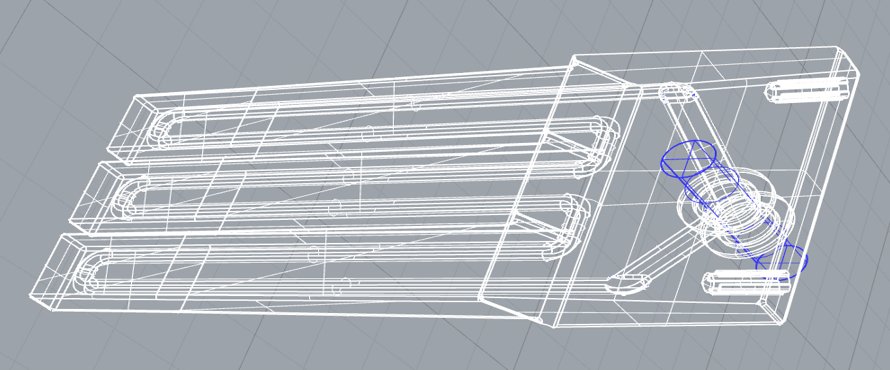

3D printed parts are made by Additive Manufacturing. Printed layer by layer and designed with conformal cooling, ultra-thin and hollow areas can be created to match complex designs. However, when traditional welding technologies are used for repair, these sections and areas can be prone to warping or cracking and other damage due to the heat generated.

Because of its low heat input, laser welding has become the go-to repair method for this new generation of tooling parts.

Precise control for repair strength

A pulsed laser beam can precisely control how much heat is introduced into the workpiece. With laser welding, the Heat Affected Zone (HAZ) is only 0.004 – 0.01 mm and the workpiece is softened in that HAZ by just 2-4 points on the Rockwell scale. Compare this to conventional welding where the HAZ would be 0.10 mm deep or more and the workpiece softened by 15-22 Rockwell points.

Heat generates grain growth and when grain size grows, the metal becomes weaker. Laser welding generates so little heat into the workpiece, you can put your hand on it immediately after completing the welding process. The workpiece’s colour won’t have changed and the welded part can be machine finished straight away

Cost-effective solution

3D printed parts cost considerably more than those manufactured by traditional methods. If the part has been damaged or misprinted, it can be repaired with laser welding – with absolutely minimal damage, regardless of the material it was made from. With pulsed laser welding, the base material and welded materials are bonded, not forced to dilute, eliminating porosity or cracking.

Laser welding applies metal to the defect area without spreading to adjacent surfaces, greatly reducing rework times.

One of our product partners is Alpha Laser, leaders and specialists in laser welding. Most of the laser welding systems we supply on their behalf are capable of welding 3D printed parts. For details on these and more information on the full range of Alpha Laser’s laser machines and systems, please contact sales@tlm-laser.com