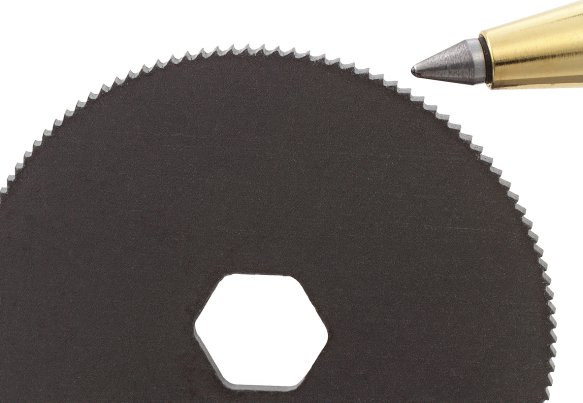

Laser Cutting Metal?

Organic to Metal – One Giant Step

Organic to Metal – One Giant Step

To expand into laser metal cutting from organic materials, you need both power and £££s.

You’ve been cutting paper, acrylics and wood as well perhaps. So it won’t be that much of a leap to start cutting metal as well, will it? Afraid the answer is yes it will. In fact, some say it’s the difference between riding a skateboard to driving an F1 car!

The problem in cutting metal is that it bows with the heat from the laser. As the material bends, so the focal height changes causing the material to rise and flow and create all sorts of deviations that affect precision and accuracy.

CO2 or Fiber Laser?

With their small spot size and better depth of field, fiber lasers are an excellent choice for a high volume metal cutting operation. But your initial investment will require a substantial amount of funds and you really do need a continuous cutting requirement to justify it.

Technological Advances

With technological advances such as capacitance height sensing, CO2 lasers have managed to keep pace with the new kids on the block. The technology deals with the focal height changes created by the heat of the laser by providing active Z axis control. This maintains a consistent and constant stand-off distance between the cutting nozzle and the metal by sensing the capacitance between both pieces.

Laser Cutters

Expanding from cutting organic material to cutting metals is neither simple nor cheap. As UK product partners and distributors for IPG Industrial Laser Cutters we can help you find a solution to meet both your organic and metal cutting needs. Just contact sales@tlm-laser.com